Ukuze kuhlangatshezwane nemithethonqubo ye-GMP, amakamelo ahlanzekile asetshenziselwa ukukhiqiza imithi kudingeka ahlangabezane nezidingo zezinga elifanele. Ngakho-ke, lezi zindawo zokukhiqiza ezingasebenzi kahle zidinga ukuqapha okuqinile ukuqinisekisa ukuthi inqubo yokukhiqiza iyalawuleka. Izindawo ezidinga ukuqapha okubalulekile ngokuvamile zifaka isethi yesistimu yokuqapha izinhlayiya zothuli, ehlanganisa: isikhombikubona sokulawula, imishini yokulawula, ikhawunta yezinhlayiya, ipayipi lomoya, uhlelo lwe-vacuum kanye nesofthiwe, njll.

Kufakwa ikhawunta yezinhlayiya zothuli lwe-laser yokulinganisa okuqhubekayo endaweni ngayinye eyisihluthulelo, futhi indawo ngayinye iqashwa njalo futhi ithathwe amasampula ngomyalo wokuvuselela ikhompyutha yendawo yokusebenza, futhi idatha eqashwe idluliselwa kwikhompyutha yendawo yokusebenza, futhi ikhompyutha ingabonisa futhi ikhiphe umbiko ngemuva kokuthola idatha kumqhubi. Ukukhethwa kwendawo kanye nenani lokuqapha okunamandla kwezinhlayiya zothuli ku-inthanethi kufanele kusekelwe ocwaningweni lokuhlola ubungozi, oludinga ukumbozwa kwazo zonke izindawo ezibalulekile.

Ukunqunywa kwendawo yokuthatha isampula yekhawunta yezinhlayiya zothuli lwe-laser kubhekisela kulezi zimiso eziyisithupha ezilandelayo:

1. Imininingwane ye-ISO14644-1: Egumbini elihlanzekile lokugeleza eliqondiswe ohlangothini olulodwa, imbobo yokusampula kufanele ibheke ohlangothini lokugeleza komoya; ekamelweni elihlanzekile lokugeleza elingaqondisiwe uhlangothi olulodwa, imbobo yokusampula kufanele ibheke phezulu, futhi isivinini sokusampula embobeni yokusampula kufanele sisondele ngangokunokwenzeka esivinini sokugeleza komoya sangaphakathi;

2. Umgomo we-GMP: ikhanda lesampula kufanele lifakwe eduze kokuphakama kokusebenza kanye nendawo lapho umkhiqizo uvezwe khona;

3. Indawo yokuthatha isampula ngeke ithinte ukusebenza okuvamile kwemishini yokukhiqiza, futhi ngeke ithinte ukusebenza okuvamile kwabasebenzi enqubweni yokukhiqiza, ukuze kugwenywe ukuthinta isiteshi sezokuthutha;

4. Indawo yokuthatha amasampula ngeke ibangele amaphutha amakhulu okubala ngenxa yezinhlayiya noma amaconsi akhiqizwe umkhiqizo ngokwawo, okubangela ukuthi idatha yokulinganisa idlule inani elinqunyelwe, futhi ngeke ibangele umonakalo ku-particle sensor;

5. Indawo yokuthatha isampula ikhethwa ngaphezu kwendawo evundlile yephuzu eliyisihluthulelo, futhi ibanga elivela endaweni eyisihluthulelo akufanele lidlule u-30cm. Uma kukhona ukuchitheka koketshezi noma ukugcwala endaweni ekhethekile, okuholela emiphumeleni yedatha yokulinganisa edlula izinga lesifunda laleli zinga ngaphansi kwezimo zokukhiqiza ezilingisiwe, ibanga eliqonde ngqo linganqunyelwa. Phumula ngokufanele, kodwa akufanele lidlule u-50cm;

6. Zama ukugwema ukubeka indawo yokuthatha isampula ngqo ngaphezu kokudlula kwesitsha, ukuze kungabangela umoya owanele ngaphezu kwesitsha kanye nokuxokozela.

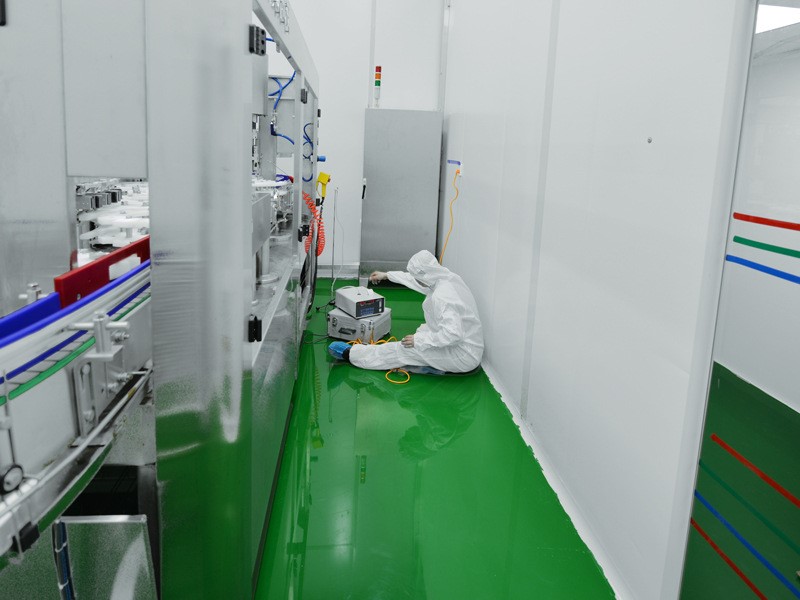

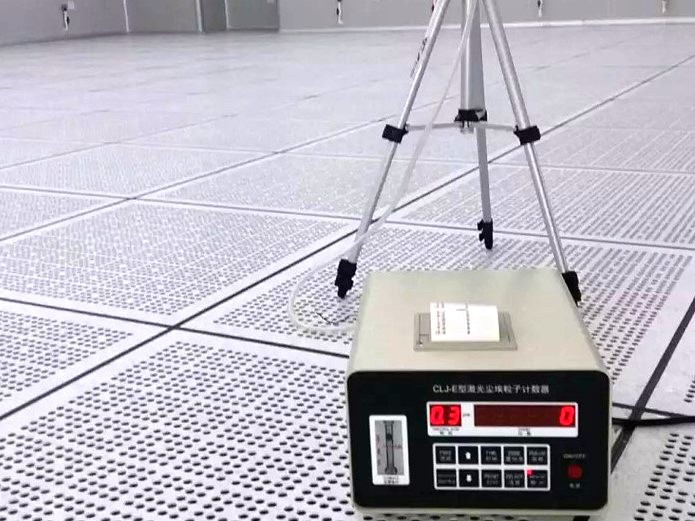

Ngemva kokuba wonke amaphuzu afanele ukutholakala, ngaphansi kwezimo zendawo yokukhiqiza elingisiwe, sebenzisa ikhawunta yezinhlayiya zothuli lwe-laser enesilinganiso sokugeleza kwesampula esingu-100L ngomzuzu ukuze uhlole iphuzu ngalinye elifanele endaweni ngayinye eyisihluthulelo imizuzu eyi-10, bese uhlaziya uthuli lwawo wonke amaphuzu okuqoqa idatha yesampula yezinhlayiya.

Imiphumela yokuthatha amasampula yamaphuzu amaningi afanele endaweni efanayo iyaqhathaniswa futhi ihlaziywe ukuze kutholakale indawo yokuqapha enobungozi obukhulu, ukuze kutholakale ukuthi leli phuzu liyindawo efanele yokufaka ikhanda lokuhlola izinhlayiya zothuli.

Isikhathi sokuthunyelwe: Agasti-09-2023